Whether you’re working with wood or metal, getting a smooth, precise, and clean cut is essential for any project. And getting those qualities in your cuts requires choosing the right saw blade or router bit.

There are a wide variety of saw blades and router bits for all types of materials, and while many may be sufficient for the job, choosing the right one can make the difference between cuts that are merely adequate and cuts that take your woodworking and metalworking to the next level of craftsmanship, beauty, and durability.

When you’re choosing a saw blade for your next project, ask yourself these questions:

What type of saw are you using?

Using a saw blade that’s not compatible with your saw will not only produce poor-quality cuts, but it may even be dangerous. Whether you’re using a table saw, compound miter saw, sliding compound miter saw, or radial-arm saw, make sure the saw blade you choose is fully compatible.

How thick or hard is the material you’re cutting?

Thicker metals or wood types require saws with bigger blades. Similarly, hard materials require saws with larger teeth. Crosscut blades can have anywhere from 60 to 80 teeth, making them good choices for hard materials, as they produce cleaner cuts and smoother cut surfaces.

How complex is the pattern you’re cutting?

If you’re making cuts that require extreme precision and accuracy—such as with complex patterns that involve fine lines and changes of direction—you’ll need to choose a blade with small teeth.

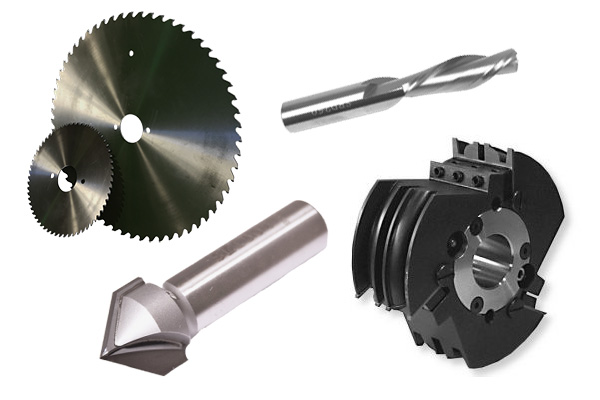

Differences between Router Bits

There are a handful of unique router bits, and each has its own unique properties:

Straight bits

These are among the most common router bits and are designed to form grooves or to hollow out areas for inlays.

Rabbeting bits

These bits are designed to cut rabbets—or shoulders—into pieces that will join with other pieces.

Flush-trim bits

These bits are used to trim the edges of a material to make it flush with the edge of another material.

Chamfer bits

Chamfer bits are designed to cut bevels at precise angles to produce decorative designs on the edges of surfaces.

Edge-forming bits

There are different types of edge-forming bits, but they’re all used to cut decorative edges—often during the final decorative stages of projects.

Specialized bits

Bits designed for specific purposes include molding bits, dovetail bits, drawer-lock bits, finger-joint bits, and lock-miter bits.